How to 3D print an Ion Mobility Spectrometer

- goodgreenlife

- 6 days ago

- 6 min read

Updated: 6 days ago

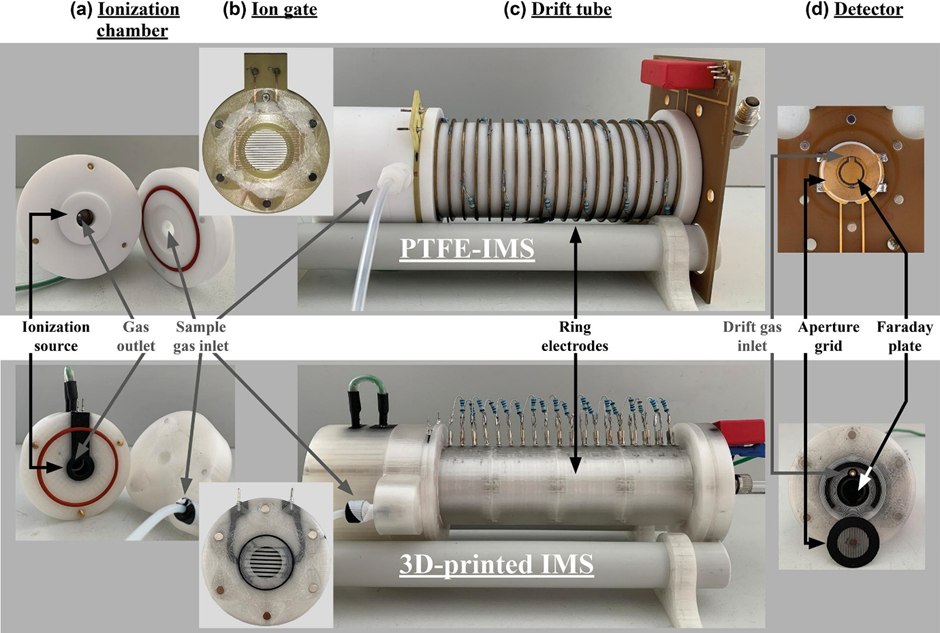

The aim of this guide is to explain how to make a 3D ion mobility spectrometer for the beginner i.e. myself using the paper written by Sebastian Brandt and others at ISAS in Germany (link). Supposedly it should take a user 1 day and 9 hours to make a DTIMS (Drift tube Ion mobility spectrometer) when you have all the relevant materials and machinery on hand. According to the author, the fundamental principle is that every functional IMS component should be independently printable, testable and replaceable. I look forward to trying this when I have stable accommodation.

Finding guides on how to make a mass spectrometer has been considerably difficult and something I am actively looking into. Note there has been a more recently published paper (April 2024) by him on manufacturing of drift tubes using additive manufacturing with coaxial filament (link). In addition there’s also an article on Flexible Drift tube for High Resolution Ion Mobility Spectrometry (Flex-DT-IMS) by Simon Maher and others worth reading (link). As well as another guide for a print in place IMS by Hauck (link). But for now, I’ll keep it simple and to one paper.

Core System Architecture

The instrument consists of 5 main functional modules all designed to be printed separately

1. Ionisation chamber

2. Bradbury-Nielson gate

3. Drift tube with field electrodes

4. Detector (aperture grid + Faraday plate)

5. Modular housing + magnetic connectors

Bradbury-Neilson is an electrical ion gate used as an electron filter. Faraday plate or an electron multiplier convert the ions into current, which allows for their quantification.

Parts List

3D Printing Equipment

Ultimaker 3 (or similar dual-extrusion FDM 3D printer)

Ultimaker 2 (or printer with interchangeable nozzles for fine details)

Nozzles: 0.4mm ID (×2), 0.25mm ID (×1), 0.1mm ID (×1)

Printing Materials

Non-conductive PLA (clear) - EasyFil PLA or equivalent (~500g)

Conductive PLA (black) - Proto-Pasta Electrically Conductive Composite PLA (~300g)

Electronic Components

Ionization source: ⁶³Ni β-radiator (550 MBq) - Requires regulatory approval and licensing

High voltage power supply: 5 kV output

Resistors: 19× 1 MΩ resistors (for drift tube electrode cascade)

Solder pins: ~30 pieces for electrical connections

BNC connector: 1× (Amphenol RF or equivalent)

Data acquisition board: Custom or commercial IMS controller

Control unit: For gate timing and signal processing

Hardware & Fasteners

Neodymium magnets: 4×2mm, 450g magnetic force (~24 pieces)

Sealing rings (O-rings):

40×2mm MVQ 30 (×1)

24×1mm MVQ 55 (×1)

22×1.5mm MVQ 50 (×1)

15×2mm MVQ 40 (×4)

Screws: Assorted small screws for ionization chamber assembly

Gas Handling

Nitrogen gas (purity 6.0 or higher)

Gas flow controller: For 300 mL/min drift gas flow

Tubing and fittings: For gas connections

Software

· CAD software: Autodesk Inventor Professional (or FreeCAD, Fusion 360)

· Slicing software: Cura 4.4.1 or later

· G-code editor: Repetier Host 2.1.6 (for fine detail work)

· Data analysis: Custom software or OriginPro for spectrum analysis

Construction Guide

Step 1: Design Preparation

Create or download CAD files for all IMS components:

Ionization chamber (2 parts)

Bradbury-Nielsen gate mounting

Drift tube (4 parts: 2 flanges, electrode section, housing)

Detector assembly

Export designs as STL files from your CAD software

Configure slicing software with these base settings:

Layer height: 0.1mm

Wall thickness: 1.6mm

Conductive PLA: 220°C nozzle, 100% infill, concentric pattern

Non-conductive PLA: 205°C nozzle, 30% infill

Build plate: 60°C constant

Print speed: 70mm/s

Step 2: Print the Ionization Chamber

Components: Sample inlet system + ionization region with electrodes

Ionization Region:

Load conductive PLA (black) in left nozzle, non-conductive PLA (clear) in right nozzle

Print using dual extrusion mode

The design embeds a ring electrode and cylindrical electrode (conductive) within an insulating housing (non-conductive)

Print time: ~8-12 hours

Sample Inlet:

Print using non-conductive PLA only

Print time: ~4-6 hours

Assembly:

Insert six 4×2mm neodymium magnets into designated cavities in the ionization chamber

Install 40×2mm sealing ring

Insert ⁶³Ni β-radiator into cylindrical electrode (follow all radiation safety protocols)

Connect electrodes with wire and secure with screws

Attach sample inlet to ionization region

Step 3: Print the Bradbury-Nielsen Gate

This requires precision printing with fine nozzles

Recommended Design (Ion Gate 3):

Grid linewidth: 0.15mm

Grid line spacing: 0.25mm

Uses 0.1mm nozzle

Printing Process:

Create custom G-code using Repetier Host for ultra-fine grid lines

Print grid lines (conductive PLA) directly onto glass build plate first

Print two sets of interleaved parallel wires

Add two-layer frame (non-conductive PLA) on top

Print time: ~2-3 hours

Handle with extreme care - structures are delicate

Gate Mounting:

Print mounting bracket with dual extrusion

Insert solder pins for electrical contacts

Embed magnets for modular connection

Install 22×1.5mm sealing ring

Carefully place printed gate into mounting with press ring

Step 4: Print the Drift Tube (Optimized Design - Drift Tube 2)

Components: 2 flanges + electrode section + insulating housing

Key Design Features:

19 ring electrodes with reduced insulation thickness (0.8mm)

Inner diameter: 15.2mm

Outer diameter: 39mm

Length: 12cm

Printing Process:

Print electrode section with conductive PLA:

19 stacked ring electrodes

Minimum 2mm thickness, 100% infill

Print time: ~12-16 hours

Print insulating housing with non-conductive PLA:

Thin walls (0.8mm) between electrodes and drift region

Print time: ~10-12 hours

Print two flanges with dual extrusion:

Embed magnets in both flanges

Install 15×2mm sealing rings

Print time: ~4-6 hours each

Assembly:

Insert 19 solder pins into electrode contact points

Connect electrodes with 1 MΩ resistors in series (creates voltage cascade)

Assemble electrode section into housing

Attach flanges to both ends with sealing rings

Verify all electrical connections

Step 5: Print the Detector

Components: Faraday plate + aperture grid + housing

Aperture Grid:

Use 0.1mm nozzle with conductive PLA

Print outer conductive frame first

Add grid lines (~100μm linewidth)

Print time: ~2-3 hours

Detector Body:

Use dual extrusion mode

Print with electrodes facing build plate for smoothest surface

Design includes three concentric structures:

Inner Faraday plate (conductive)

Ground shield ring (conductive)

Outer connector ring (conductive)

All embedded in non-conductive housing

Print time: ~6-8 hours

Assembly:

Press BNC connector into housing

Insert solder pins for connections

Install 24×1mm sealing ring

Embed magnets for modular connection

Mount aperture grid with drift gas inlet between grid and Faraday plate

Step 6: System Integration

Electrical Connections:

High voltage cascade: Connect drift tube resistors from ionization chamber (5kV) down to detector (ground)

Gate control: Connect Bradbury-Nielsen gate wires to control unit

Signal detection: Connect Faraday plate to data acquisition board via BNC connector

Ground connections: Ensure proper grounding throughout

Gas System:

Connect nitrogen supply to drift gas inlet at detector

Set flow rate to 300 mL/min

Connect sample inlet for analyte introduction

Connect gas outlet from ionization chamber

Modular Assembly:

Align ionization chamber to gate mounting using magnets

Attach gate mounting to drift tube flange using magnets

Connect drift tube to detector using magnets

Verify all sealing rings are properly seated

Step 7: Initial Testing & Calibration

Running-In Period:

Power on system with drift gas flowing

Allow 24-hour stabilization period for drift time equilibrium

Monitor reactant ion peak (RIP) position and intensity

Gate Timing:

Set ion gate opening time: 300μs

Set repetition cycle: 50ms

Adjust as needed for your application

Performance Verification:

Measure RIP characteristics:

Drift time should stabilize at ~16.7ms (with nitrogen drift gas)

Signal intensity should be stable

Peak width (FWHM) ~0.38-0.50ms

Test with calibration standards (e.g., ketone isomers)

Calculate resolving power: should achieve 40-50

Measure signal-to-noise ratio: target >200

Safety Warnings

⚠️ CRITICAL SAFETY REQUIREMENTS:

Radioactive Material: The ⁶³Ni source requires:

Proper licensing and regulatory approval

Radiation safety training

Appropriate shielding and handling procedures

Compliance with local radiation safety regulations

High Voltage: 5kV system requires:

Proper electrical safety training

Insulated tools and work area

Emergency shutoff accessible

No work on live circuits

Compressed Gas:

Proper gas cylinder handling and storage

Appropriate regulators and pressure relief

Adequate ventilation

Troubleshooting

Problem: Drift time shifts over time Solution: Ensure insulating layer in drift tube is ≤0.8mm thick. May require 60+ hour stabilization with thicker designs.

Problem: Low signal intensity Solution: Check electrode connections, verify gas flow rates, consider activating 3D-printed Faraday plate surface.

Problem: Poor peak resolution Solution: Verify gate timing (300μs), check for gas leaks at sealing rings, ensure uniform electric field in drift tube.

Problem: Gate not closing properly Solution: Verify voltage levels on gate wires, check for wire damage, ensure proper gate mounting alignment.

Performance Expectations

With this optimized design, you should achieve:

Resolving power: 40-50

Signal-to-noise ratio: 220-250

Resolution (for isomers): 1.4-1.8

Drift time stability: Within 0.3ms of commercial systems

Running-in time: ~24 hours

Cost & Time Estimates

Total printing time: ~60-80 hours Material cost: ~$150-200 (filaments only) Electronics cost: $500-2000 (depending on components chosen and country you are in) Total project time: 2-3 weeks including printing, assembly, and calibration

For details on what to print please see Supplementary data (link)

Comments