Manufacturing

- goodgreenlife

- 3 days ago

- 11 min read

Manufacturing has a rich history. Prior to the 19th Century everything was made by Artisans. Products were handmade by individuals or teams of craftsmen, creating each part of a product with every product being slightly different. There are ancient historical examples of the assembly line, for example the Venetian Arsenal in 1104 producing prefabricated ships assembling them in as little as one day. But I will start closer to the present day.

Not all knowledge persists; many discoveries, inventions and ideas have been lost over time. Whether due to war or societal collapse, or deliberate suppression or simply due to death or shifts in culture and scientific methods. Knowledge can be lost.

In 1793 Eli Whitney Jr. an American inventor, invented the cotton gin, one of the key inventions of the Industrial Revolution that shaped the economy of the Antebellum south. The gin separated the sticky seeds from the fibres in short-staple cotton, which was easy to grow in the deep South but difficult to process. He went to the north and took on the project of producing muskets which led to the invention of the milling machine and realised the process of mass production. Which is the idea of small interchangeable parts, you make many of one type of piece and if that broke you swapped it out.

In the Early 1900’s Henry Ford revolutionised manufacturing with the introduction of the Model T. He had a relentless focus on efficiency which meant constant refinement of processes, from factory design to layout to part design. The aim being, to lower the cost and increase the output. By breaking down manufacturing into small steps, anyone could do that step. The result being Ford’s Highland Park having a car coming off the assembly line every 3 minutes. This was much faster than previous methods, increasing production by 8 to 1. Previously it required 12.5 man hours before to produce a car, now it only took 1 hr 33 minutes. It was so successful that paint became a bottle neck. Only Japan black would dry fast enough forcing the company to drop the variety of colours available before 1914, until fast drying Duco lacquer was developed in 1926. Early factories were dangerous, in 1911 200 fingers were severed. But the work force was happy as he more than doubled the daily wage of workers. The cost of vehicles was reduced such that an assembly line worker could buy a Model T with 4 months’ pay.

In early 1900s Kiichiro Toyoda introduced lean manufacturing. The five areas that drive lean manufacturing are: cost, quality, delivery, safety and morale. Lean manufacturing is also known as just in time manufacturing; all the parts arrive just as you need them, eliminating the need for parts storage warehouses. He also introduced the idea of kaizen, continuous improvement philosophy. Based on continuous improvement by everyone. Flexible Management Systems (FMS) adapting efficiently to changing needs, possibly increasing productivity by 50%. (Note: The word "Toyoda" uses ten Japanese strokes to write while "Toyota" uses only eight. Eight is considered a lucky number in Japanese culture.)

In the mid 1900s Jervis B. Webb Co. create the first electronically coordinated conveyor system. Creating both the ASRS and AGV. Automatic Storage and Retrieval System (ASRS) moves material vertically or horizontally between storage compartment and transfer station or within a process. Automated guided Vehicles (AGV) are computer-controlled system using pallets to transport work pieces to NC machine tools and equipment in a flexible manufacturing system. He created the rivetless chain conveyor, which was extremely strong and can easily be coupled and dismantled without using tools. It also offered the advantage of flexible production line as the rivetless chain can adapt to curves and slopes. These chains were supplied to manufacturers like Ford Motor Company and significantly contributed to industrial progress in North America (link).

Manufacturing Today

Today there are many manufacturing systems, before I talk on modern experts, I thought it pertinent to note some of the types of manufacturing and their terms.

Terms:

Artificial Intelligence (AI). Machines learn from experience and knowledge is used to problem solve.

Computer Integrated manufacturing (CIM). Companywide management philosophy for planning, integration and implementation of automation. Manufacturing Enterprise Wheel is customer centred, people and teamwork, shared knowledge, key processes, resources and responsibilities and infrastructure.

Just in Time Manufacturing (JIT). The objective is to eliminate waste, it’s capable of producing mixed products and utilises cross trained workers.

Toyota Production System (TPS) Applied to automotive manufacturing, competes with mass production. Employs lean production strategy.

Lead Manufacturing. Systematic elimination of waste. Entire system must participate to produce effectivity.

Six Sigma (6σ). It indicates measure of quality for near perfection. Producing fewer than 3.4 defects per million opportunities. Identifies and corrects causes of defects, utilising the five “whys” to uncover root cause.

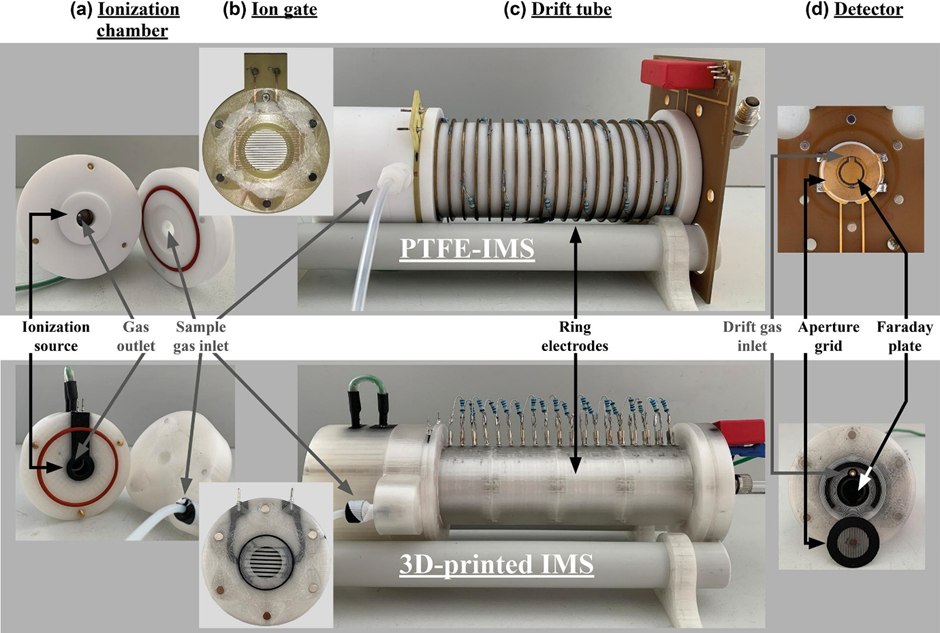

Rapid Prototyping. Prototypes made directly from a computer model. Several technologies are employed including stereolithography, 3D printing, selective laser sintering and fused deposition modelling. Workcells are manufacturing resources arrange into a group. Work envelope is the range of motion of a robot or machine; degrees of freedom are individual movements.

Modern Experts

Some of the most innovative companies today in manufacturing are Tesla, Apple, Dyson.

Though in slightly different fields these individuals have been incredibly successful in terms of company market cap, units delivered and complexity of products produced.

Elon Musk is known for hardware start ups both with Tesla and SpaceX. “prototypes are easy, production is hard” highlights his belief in execution as the critical product in innovation. Typically, his companies are designed with production managers, engineers and designers sitting next to each other so that they share ideas freely and have a better understanding of how their work affects others. For example, a designer may suggest an idea, but a person working in engineering or manufacturing would quickly be able to see the difficulty and suggest an alternative. This interwoven collaborative approach prevents friction within teams due to the rapid communication. After reading Walter Isaacsons biography you learn that Musk has an algorithm at teach of his production sites:

1. Question every requirement 2. Delete any part of the process you can 3. Simplify and optimise 4. Accelerate cycle time 5. Automate

Musk also makes mostly everything in house. Strongly prioritising vertical integration and insourcing when they believe they can achieve better quality, lower cost or faster development than external suppliers. Co-locating design and manufacturing allows for rapid iteration which is much more difficult and slower when dealing with external manufacturers. In addition, with Space X, traditional aerospace outsourcing often involved spreading contracts across many different congressional districts for political support, which lead to inflated prices and inefficiencies.

When Tesla struggled to meet Model 3 demand in 2018, Musk came up with an unorthodox solution by building an assembly line inside a giant tent outside the Fremont factory in 3 weeks. Helping Tesla hit its goal of 5,000+ model 3 cars per week (link). Musk’s philosophy is that the machine that build the machine is a product itself. With regard to simplification “the best part is no part” meaning that you must remove unnecessary components to streamline production.

Tim Cook

Though Tim Cook was not a founder he still has had an incredible influence on hardware manufacturing through his supply chain expertise at Apple. He believes in lean supply chains, reducing inventory to zero for just in time production as well as building tight partnerships with contract manufacturers like Foxconn. This allows Apple to handle huge spikes in demand such as when a new iPhone launches. Here’s an excerpt from the book “Tim Cook: The Genius Who Took Apple to the Next Level”

“Back when Cook joined Apple, forecasting demand and improving supply chains wasn’t cool in the same way that creating candy-colored computers was cool. No one was lining up to make Apple’s operational overhaul the cover story on Fortune or Wired, and to the average customer. In the seven months after he started work at Apple, thanks to Cook’s achievements slashing inventory turnover from thirty days to six, the company’s inventory stock was reduced from $400 million worth of unsold Macs down to just $78 million.”

Cook understood that Apple is fundamentally a product company.

Extreme Manufacturing Feats: Past and Present

World War II (production)

History offers dramatic examples of scaling up manufacturing to unprecedented levels. In the early 1940s the US and its allies mobilized industry to staggering levels, converting civilian factories into wartime producers. Henry Ford’s auto plant started churning out B-24 bombers and shipyards began mass producing cargo ships using assembly line methods. The Liberty Ships program demonstrated extreme throughput. These were simple cargo ships built from prefabricated section welded together in pieces. At the beginning of the war a single ship took 355 days and 1.4 million man hours to build, by 1943 the U.S. yards had cut that to an average of 41 days per ship and under 500,000 man hours. The SS Robert e. Peary was a Liberty ship that gained fame during WWII being built in just 4 days 15 hrs and 29 minutes after the keel was laid down (link).

LEGO (precision and quality at scale)

Another example of extreme manufacturing is LEGO demonstrating precision and quality at huge scale. The Danish toymakers produce tens of billions of plastic bricks per year with a defect rate of 18 bricks per million manufactured. In fact due to the high tolerance of models being within 0.001 mm, every brick is made such that it can connect with bricks as far back as 1958(link).

Lights out factories are where robots work autonomously. FANUC has been operating as a lights out factory since 2001. Approximately 50 robots are built in every 24 hour shift and production can run unsupervised for as long as 30 days at a time. In the US lights out manufacturing has slowly been transforming the plastic injection moulding sector. Makuta Micro Molding is a company which specialises in micro injection moulding and micro moulding tools, producing millions of zero defect micro to small sized parts monthly for the medical, pharmaceutical and microfluidics and automotive industries. Humans are only required to set up the machines for each production run. Despite the benefits in reduced labours costs and fewer worker accidents it is a complex, resource intensive process (link).

Global Perspectives: How different cultures innovate in manufacturing

As a westerner many of my examples of manufacturing have been about US and Japanese companies even though the bulk of world manufacturing is done in China.

China and the Shenzhen Ecosystem

China is the manufacturing capital of the world. Shenzhen was once a fishing village but now produces over 90% of the worlds electronics and has a nominal GDP of $330 billion. The city has over 3 million registered businesses, meaning one enterprise for every 4 people. Its strength lies in its sheer scale, speed and supply chain depth. The city’s electronic markets like Huaqiangbei offer components by the pound. When it comes to prototyping Shenzhen is incredible, in the UK it’ll take you around a month to make something which is specialist, where as an engineering firm in Shenzhen can do it in a couple of days. Due to the ability to buy thousands of version of circuit boards, LEDs, microchips… in bulk and very low cost, engineering parts get turning into prototypes overnight. There are draw backs like weak intellectual property rights and frequent infringement but this has given way to open source designs with thousands of engineers and tinkers collaborating across products, building progressively better iterations and letting the market claim a winner. The ecosystem has birthed a generation of “gladiator entrepreneurs” each zooming to get products to marker and meet demand overnight and iterate adjacent products before others innovate over them (link).

In Europe if you were to think about manufacturing, perhaps countries like Germany would come to mind. Currently Germany is spearheading Industry 4.0 with the integration of digital technologies into manufacturing. Firms like BMW, Siemens and Bosch focus on automation, sensors and data driven process optimisation. With Internet of things devices monitoring every machine (link). Europe also emphasizes training and workforce skills resulting in high quality and efficient production. BMW is able to produce a custom order car in 40 hours with each car combing off the line being different because of flexible robotic cells and advanced logistics.

Future of manufacturing

To keep this brief I won’t go into great detail and will lean heavily on an excellent article. We have seen the rise of industry 4.0 and smart factories. Other innovations are collaborative robots (cobots) which can work alongside humans without safety cages, assisting with tasks like assembly or packing. This augments labour, rather than simply replacing it. However, this may be short lived with the arrival of humanoid robots. Elon announced the Optimus robot, aiming for 10,000 robots in each factory by 2025. Though these have halted the mass production of these robots citing design challenges, it’s not impossible to see how eventually they will work and potential remove the delicate dexterous ability of humans from manufacturing all together (link).

A really interesting article from StartUs insights talks about trends for the next decade of manufacturing growth (link). The main points are copied below:

“Manufacturing is undergoing a deep transformation as AI, automation, and climate pressure are forcing faster, leaner, and smarter operations. The trends driving this shift through 2026 to 2035 are:

AI-Native Factories: Fully autonomous production sites reduce energy use by 30%, and minimize defects by 99%. Companies like Tesla and Siemens are scaling “lights-out” operations powered by AI.

Regionalized, Low-Carbon Supply Chains: 85% of manufacturers aim to regionalize by 2026 to avoid rising CBAM tariffs and reduce freight emissions. Apple, Zara, and Schneider Electric are already moving production closer to demand.

Workforce Augmentation & Cobots: With 1.9 million US manufacturing jobs projected to go unfilled by 2030, companies like Hyundai and Sandvik are adopting exoskeletons, AI copilots, and AR/VR training to boost productivity and safety.

Predictive Maintenance AI + 5G Edge: Predictive maintenance reduces downtime by up to 50%. US firms lead global adoption, and platforms like FactoryAI cut data costs while ensuring uptime with edge-powered analytics.

Immersive Digital Twins & Industrial Metaverse: Digital twins cut planning cycles by 30% and support real-time simulation. BMW and Renault use NVIDIA Omniverse to optimize layouts, energy use, and factory operations.

Autonomous Mobile Robots (AMR) & Humanoid Robots: Robots fill labour gaps. Global demand for humanoid units could exceed 1.1 million by 2035.

Additive Manufacturing (AM) at Production Scale: AM reaches a USD 90 billion market by 2032. Boeing, Adidas, and General Atomics now use multi-material printing and AI-powered quality control for flight-grade parts and high-performance footwear.

Hyper-Local Microfactories: Urban factories reduce lead times and eliminate freight emissions. Shipping costs jumped since 2020, which pushed brands like Olympian Motors and Relocalize toward distributed, flexible production.

Modular & Self-Reconfigurable Cells: These cells adapt on the fly and reduce material waste by up to 90%. BMW and Volkswagen are leading pilots with AI-driven modular systems for fast changeovers.

Servitization / Equipment-as-a-Service (EaaS): EaaS will reach USD 27.8 billion by 2030. Models like ABB’s robotics-as-a-service and Synctive’s pay-per-use billing support manufacturers in boosting recurring revenue.

Scope-3 Traceability & Digital Product Passports (DPP): The EU will mandate product-level traceability by 2029. Volvo, BMW, and Schneider Electric already deploy passports that track emissions.

Corporate Sustainability Due Diligence (CSDDD): New EU rules require end-to-end risk mapping and emissions audits. Over 6000 firms must comply by 2030.

Consumer Premium for Local & Green: 74% of buyers already pay more for sustainable goods. Patagonia and Walmart prove local products can command premiums and scale affordably.”

First Principles

Manufacturing first principles are very similar to the principles given by Toyado, Ford and Musk. Flow, rate determining steps, reduction of variation, a focus on quality is cheaper than dealing with defects, production design must be easy, robust and repeatable. Energy, time and material losses are true costs, with a focus on information of the system. Flexibility with change overs of product to meet demand, reliability beats brilliance, iterate fast, test early, measure often and trace issue to root causes.

Conclusion

Some of the developments in manufacturing today are insanely impressive. Xiaomi’s AI factory assembles 1 smartphone per second with 11 fully automated lines. At Tesla’s Shanghai plant, cars roll off the line every 30 s. There are numerous incredible innovations that are happening, however it’s not all glory. Just in time manufacturing relies on fragile supply chains that are massively affected by geopolitics and black swan events like a barge being stuck in the Suez Canal (link). Demand for products like GPUs and RAM have risen massively due to AI (link). There are also talent gaps occurring, in the US over 287,000 jobs will open up due to retirement with 68% of manufacturers worrying about losing critical institutional knowledge, hiring teams are falling short only meeting 36% of hiring targets.

There is so much more to manufacturing than meets the eye, in addition companies not in manufacturing like Amazon have expertise and solved problems that most definitely overlap with problems faced currently. This is a topic that I must revisit.

Ideas are easy, execution is everything. Supply chain excellence itself is a product, one that deserves a seat at the table alongside traditional creative arts and technical innovation.

Comments